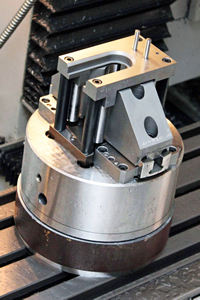

Workholding Solutions

We Start with the PartSolutions for Castings, Forgings, and Gears • Balance Cutting and Gripping Force

A company making a casting can find their part wants to distort. When you make a forging, you’re fighting the parallelism spec on the customer drawing. A gear manufacturer has challenges meeting parallelism and roundness specs. When the part is made from aluminum or another non-ferrous material, these problems can be magnified. What limits most workholding solutions is the part geometry and part material. You can therefore easily distort the part. KE&M has the expertise to help you resolve your issues meeting Parallelism, Perpendicularity and Roundness specs called out on your customer’s drawings.

KE&M reviews the drawing, determines the best way to locate and grip on the proper datum, figures out how much distortion the gripping and cutting will cause in the part, and finds the optimal solution to balance gripping force and cutting force. We then select and provide the proper chuck if needed, and always design and build the custom tooling for the recommended solution. KE&M’s years of tool & die and workholding experience combined with a strong engineering background come together to provide what is needed for part-centric solutions.

Kenyeri Engineering & Manufacturing Strengths

- Develop solutions tailored to each application – not one size fits all approach

- Experience to explore multiple approaches to processing a part

- Ability to evaluate the part and assess limiting factors

- Integration expertise

- Scientific approach and skill set (software, analysis/simulation, FEA (finite element analysis), 3D CAD modeling)

- Can evaluate not just workholding, but also cutting tools and cutting operation

- Test, installation & startup assistance can be provided

- Troubleshooting in the field